Washer-disinfectors: Choosing the right combo for your SPD

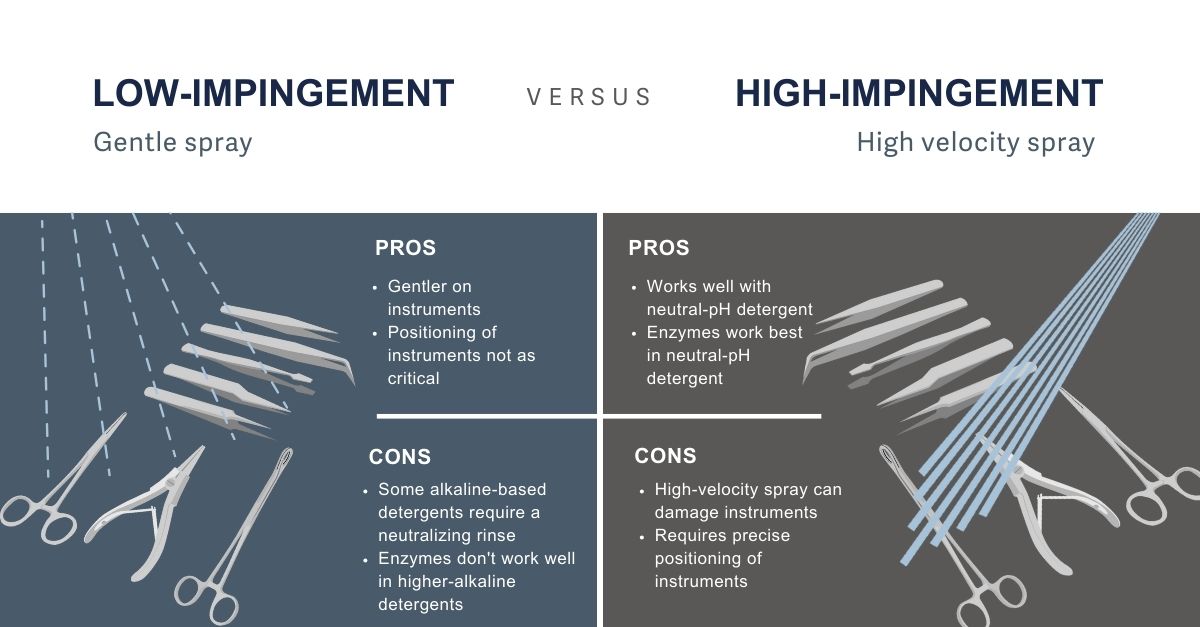

Which washer-disinfector is right for your sterile processing department (SPD)? And how do you know which chemistries to use with it? Washer-disinfectors clean everything from complex surgical instruments to laboratory glassware to bedpans. They are based on regular dishwashers and operate in much the same way. There are two different methods of cleaning with a washer-disinfector: low impingement and high impingement, although some washer-disinfectors now include both options.

Detergent dynamics: Low- vs. high-impingement washer-disinfection

Low-impingement cleaning is better for delicate instruments, such as robotics, as it uses a lower-pressure spray and is less aggressive than high-impingement cleaning, resulting in less damage to the instruments. The high velocity of the detergent-and-water spray in a high-impingement washer-disinfector can cause pitting on some instruments. Low-impingement cleaning uses water that showers the instruments rather than forcefully spraying them. This makes the detergent an important part of the cleaning process, as it must do more work than in a high-impingement washer-disinfector.

Instead, low-impingement washer-disinfectors rely on an alkaline (or higher pH) detergent to help remove bioburden from instruments. Alkaline-based detergents dissolve protein and fat residues, doing the work of the high-velocity spray jets found in high-impingement washer-disinfectors. High-pH detergents require an acidic (or low-pH) rinse to neutralize any detergent residue and prevent pitting of the instruments from it.

Innovative chemistry: Getinge's latest advances in gentle yet powerful detergents for washer-disinfectors

Advances in the lab are creating new detergents that have the same cleaning power but are gentler on the instruments and machines. Getinge’s new line of XEN chemistries includes a mildly alkaline, enzymatic detergent that works well in low-impingement washer-disinfectors. Being mildly alkaline rather than high-alkaline means the detergent is gentler on delicate instruments and doesn’t require an acid rinse to neutralize the detergent.

New enzymes, such as those used in Getinge’s XEN chemistries, have been engineered in the lab to break down the same substrates as the enzymes in neutral detergents but with a higher pH and temperature tolerance. This allows for a wider range of enzymes that act on a wider variety of substrates (proteins, fats, carbohydrates, starches, and cellulose fibers) than older, highly alkaline detergents. It also allows the detergents to be less complex and more sustainable during supply chain fluctuations.

Optimizing washer-disinfector performance: The crucial role of detergents in low- and high-impingement cleaning

Positioning of the instruments is not as critical in a low-impingement washer-disinfector as in a high-impingement one. The high-impingement washer-disinfector requires that each instrument get hit with a high-pressure spray, so they must be carefully placed. The low-impingement washer-disinfector floods the instruments with enough water and detergent mix to reach all the instruments and for the alkalinity and enzymes to provide a thorough cleaning.

High-impingement washer-disinfectors use spray arms, nozzles, and high-pressure pumps to create a high-velocity spray of water and detergent that dislodges bioburden from surgical instruments. High-impingement cleaning works best on heavily soiled instruments that require a more intense and thorough cleaning—those with complex shapes and hard-to-reach or hidden areas.

The high-pressure spray is good at removing tough residues and organic matter but is most successful when direct contact is made with the surface to be cleaned. Positioning of the instruments in the washer-disinfector, therefore, is extremely important with high-impingement cleaning. If one instrument blocks the spray from any part of another, the instrument being blocked may not be completely cleaned. This can become problematic when too many instruments are included in a load and the SPD has no set limits for instrument quantity per load.

While the detergent in high-impingement washer-disinfectors does not work as hard as that in low-impingement washer-disinfectors, it is still important to choose a chemistry that will help your equipment operate at its best. These detergents generally have a neutral pH and often contain multiple enzymes, much like the newer detergents for low-impingement cleaning. The enzymes can break down a wide range of substrates so the high-pressure spray can remove them.

The force of the impingement can sometimes damage the substrates as it forces instruments to move during the wash cycle. Damage can keep the enzymes from being able to bind with the substrates and break them apart. In this case, surfactants can help loosen the substrates to make the high-pressure spray more effective at knocking them off the instruments.

The high pressure and velocity also can cause foaming, which can clog the spray arms and jets. This ultimately reduces the spray velocity and the cleaning power of the washer-disinfector. High-impingement washer-disinfectors require a low-foaming detergent that can also reduce foam created when it encounters proteins.

If your facility has hard water (water with a high mineral content), routine descaling becomes important as well. Scale can clog the spray arms and nozzles and reduce the force of the liquid during cleaning and rinsing cycles. Detergents like the new XEN chemistries are formulated to work in all water conditions, including in areas where hardness and mineral content are known challenges to cleaning.

Low-impingement and high-impingement cleaning each have some advantages. The cleaning method by itself doesn’t guarantee success, though. The chemistries you use with your washer-disinfector make a big difference in how effective each cleaning method is. With the right chemistries, a low-impingement washer-disinfector will provide you with a thorough clean with the added advantages of sustainability and a lower long-term cost.