Use of robotic surgical instruments

The explosion of robotic surgical instruments and systems in recent years is a boon to patients, who undergo less trauma and have shorter recovery times as a result of their use. But it has only added to the burden of sterile processing departments (SPDs) everywhere.

Robotic systems allow surgeons to perform complex surgeries in a minimally invasive way, yet the instruments have become more complicated and harder to clean. In addition, the list of surgeries that can be performed with a robotic system continues to expand. It now includes cardiac, gastrointestinal, orthopedic, vascular, gynecological, urological, thoracic, cosmetic, and dental, according to Precedence Research. The number and complexity of robotic instruments seems likely to grow.

Working with robotic surgical instruments

Most robotic surgery systems include a console with a video screen that the surgeon uses to view the surgical site, along with controls to move the arms and the attached instruments that work inside the patient’s body. The instruments generally consist of the piece that connects to the robotic arm, then a long, insulated shaft housing cables that operate the articulated wrist, and a tip (grasper, needle driver, scissors, cautery tip, etc.).

The robotic arms and body are enclosed in sterile plastic covers during surgery and cleaned in place afterward. However, the instruments—made up of many moving parts—must be cleaned and sterilized in the SPD. In addition to the instrument tip, the pulley the cables run on, the shaft, and the cables themselves also are exposed to bioburden. The distal end of the shaft is open where the cables connect to the tip. As the cables move, fluids and bioburden are pulled inside the shaft.

©Intuitive Surgical Operations, Inc.

©Intuitive Surgical Operations, Inc.

Ultrasonic irrigation and cleaning

In the SPD, manual reprocessing of robotic instruments is usually the first step but cannot be the only one. Manual brushing can’t always reach into the small crevices and narrow lumens. In addition, metal brushes can leave scratches or pitting, which can lead to biofilm buildup and the spreading of bacteria.

Removing all soil and bioburden is imperative, though, to prevent corrosion and instrument damage, as well as the spread of bacteria between patients or to staff. The fine cables are prone to developing biofilm and corrosion, which can lead to surgical site infections or instrument failure. If an electrocautery instrument’s insulation is damaged, it can even cause electrical discharges and burns inside the body.

Most robotic instrument manufacturers’ instructions for use (IFUs) now recommend ultrasonic irrigation and cleaning for their instruments. Ultrasonic cleaners can gently remove blood, fluids, and soil from joints, hinges, and interior spaces on lumen and robotic instruments. They use a mixture of water and an enzymatic detergent to soften and lift off sticky residues. Cavitation created by the ultrasonic transducers produces a vacuum and scrubbing action that cleans the most delicate parts of the robotic instruments without harming them.

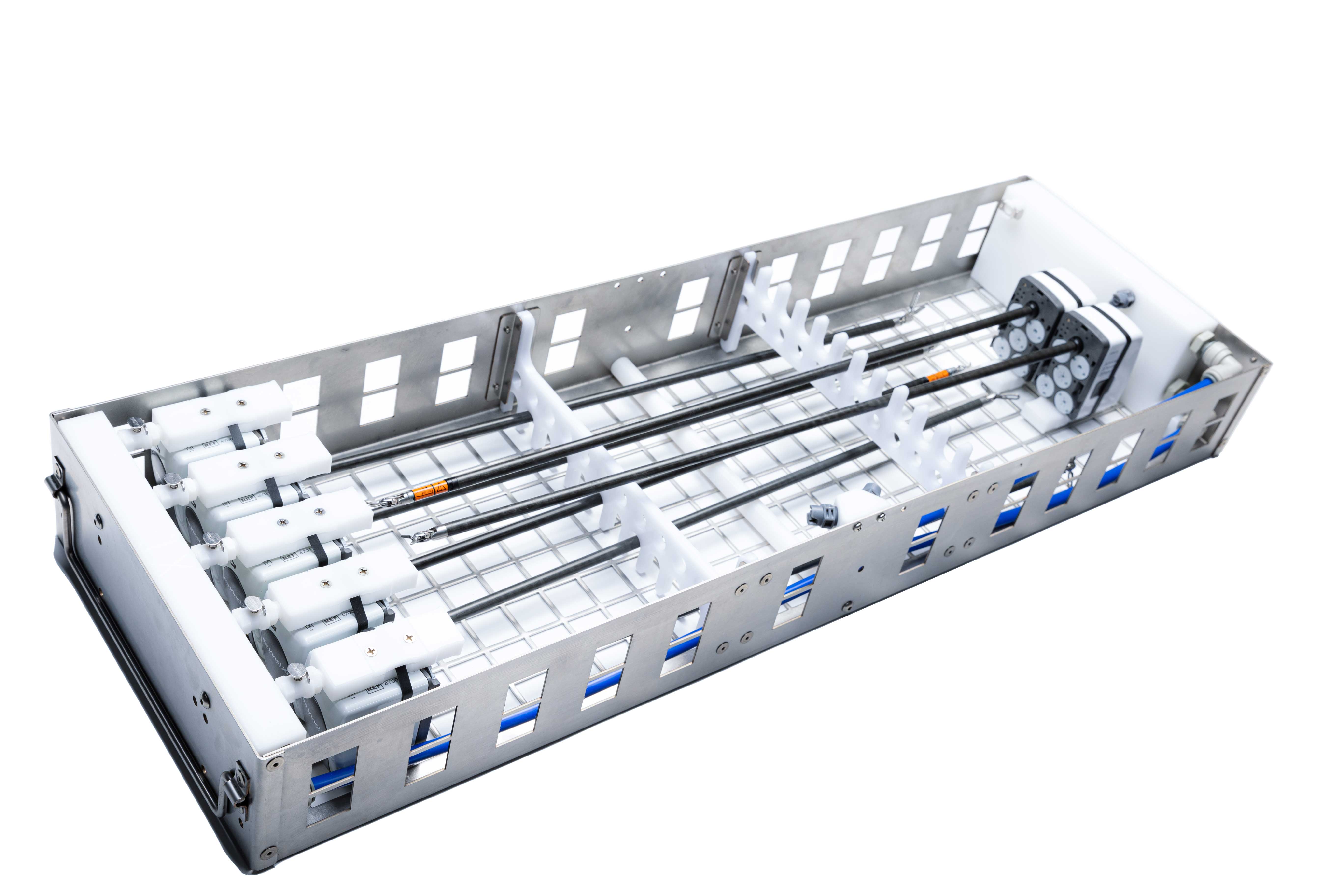

Ultra Clean’s ultrasonic cleaning systems are made to thoroughly process DaVinci® robotic instruments. With specially designed instrument trays and adapters, they irrigate the robotic instruments’ shafts, using cavitation to scrub hard-to-reach places. Both detergent and bioburden can then be flushed from the instruments with an automatic rinse and air purge.

Our solution

Our Triton series ultrasonic cleaners add an extra layer of protection with ultraviolet (UV) water treatment. As the water enters the basin and is recycled through the instruments during the cleaning cycle, it passes over a UV light, deactivating harmful microbes and providing you with a superior clean.