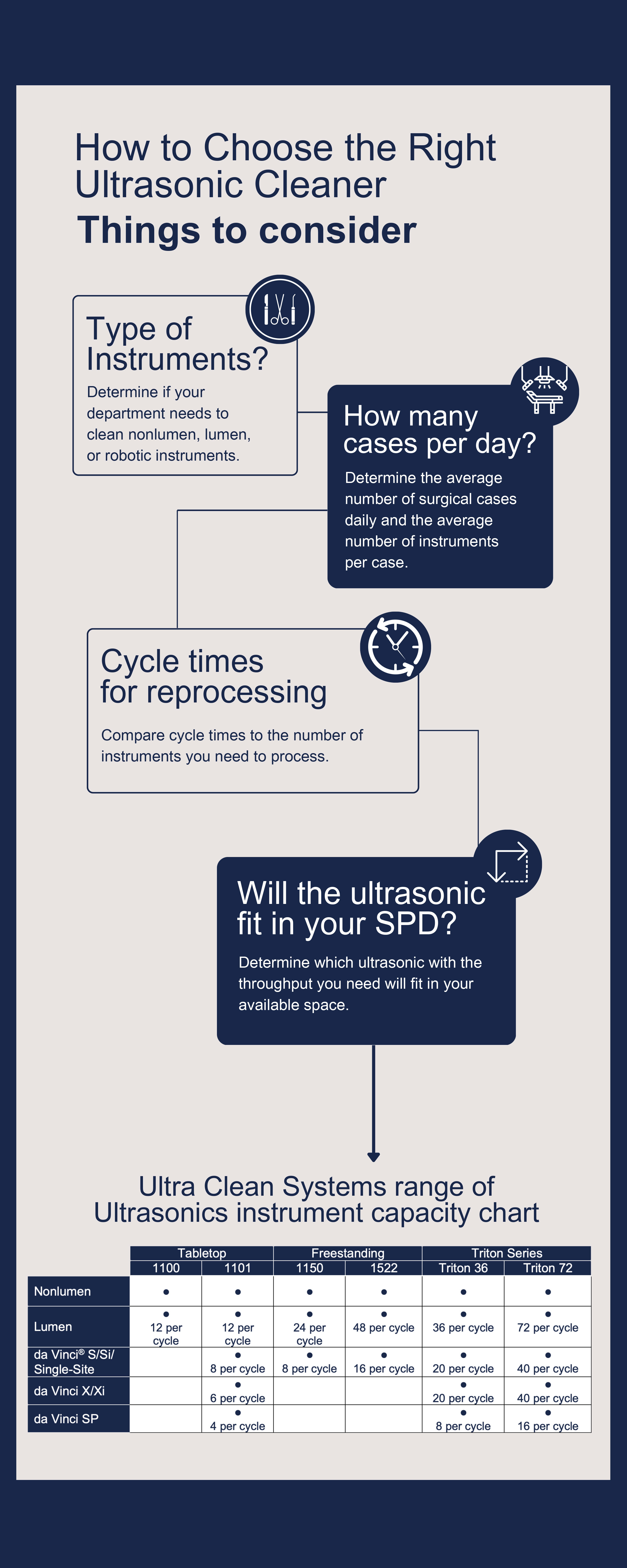

What do you need to know to choose the best ultrasonic surgical instrument cleaner for your sterile processing department (SPD)? There are several things to consider. The most important are the number and type of instruments your department reprocesses on its busiest days and the space available for your machine.

An ultrasonic washer provides a more thorough cleaning of surgical instruments than a manual scrub. Enzymatic detergent helps loosen bioburden while cavitation lifts the soil free. Because of their ability to safely reprocess delicate surgical instruments, ultrasonics are recommended or required in the instructions for use (IFUs) for most laparoscopic and robotic instruments.

How many instruments?

Determining the total number of instruments your department is asked to turn around each day is only the beginning. Can the ultrasonic cleaner irrigate lumen instruments? If your facility owns a robotic surgery system, your ultrasonic cleaner must comply with the IFUs for the system’s instruments.

Determine the average number of surgical cases scheduled daily along with the average number of instrument sets each case requires. Then look at the peak times in your SPD and calculate the largest possible number of instruments that will need reprocessing at the same time.

Break that number down by instrument type. Compare the number of nonlumen instruments, which don’t require irrigation, to the load capacity of the ultrasonic cleaner. Some orthopedic instruments are large and heavy. The number of lumen or robotic instruments is limited by the size of the instruments and the number of irrigation ports available in the machine.

Cycle times for reprocessing

Once you have those numbers, review the cycle times necessary for the various types of instruments. All Ultra Clean Systems ultrasonic cleaners have preset short (8-minute) and long (13-minute) wash cycles for lumen and nonlumen instruments. All but our most basic tabletop model have approved 15-minute wash cycles for da Vinci robotic instruments.

With robotic instruments, consider the number of instrument sets your hospital owns for each type of surgery. How often are they needed? How quickly can each set be turned around between surgeries? How many sets can be reprocessed at the same time?

The number of minimally invasive surgeries being performed has increased rapidly in recent years and is forecast to continue its upward trend. When buying a new ultrasonic or upgrading to a larger one, be sure to plan for future growth in the number of robotic surgeries and the robotic instruments that need reprocessing.

Will it fit?

Of course, one major consideration is the space available for an ultrasonic cleaner in your SPD. Higher throughput requires a larger machine. To accommodate more or longer instruments, some ultrasonic systems take up a wider space, while others project farther from the wall. Height also is important since there must be space for the lid to be opened or elevators to be raised. Backsplashes and sprayers take up vertical space as well.

Smaller SPDs with lighter reprocessing loads may prefer a tabletop model that can fit on a counter, tabletop, or storage cart. Ultra Clean Systems has two tabletop models; both must be at a height of 30" from the floor.

Placement will be affected by the connections needed for the machine to operate properly. All ultrasonic cleaners require a power connection, a water connection (possibly both cold and hot), and a drain. Some also require an air connection.

The right ultrasonic cleaner for your SPD makes you a stronger partner for your facility’s surgical teams. It can easily handle your department’s current workload and is prepared for a future increase.