North America's First Fully Digital Hospital

Powered by Getinge

Innovation doesn't happen by accident - it's the result of careful planning, design, and execution. This is exemplified in the Sterile Processing Department of Humber River Hospital, which is fully supported by Getinge's most cutting-edge technology and automation solutions.

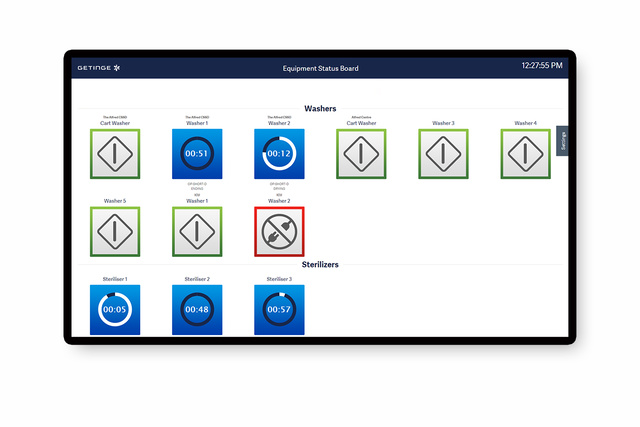

A Getinge partnership is more than products - it's about realizing a hospital's vision in a complete, future-proof solution - designing a department meant to withstand the test of time. Humber River Hospital utilizes some of the most unique and advanced Getinge Sterile Processing solutions including washer and sterilizer automation and multi-chamber washers.

From Concept to Reality

The Sterile Processing Department is at the heart of the hospital, serving as the last point of contact for instruments before they touch a patient. That's why it's critical that every element of the department from workflows, to equipment, to ergonomics, to consumables and instrument tracking is optimized.

That's why Humber River Hospital partnered with Getinge.

Partners in Sterile Processing Excellence

Case Story: A Getinge Sterile Processing Partnership

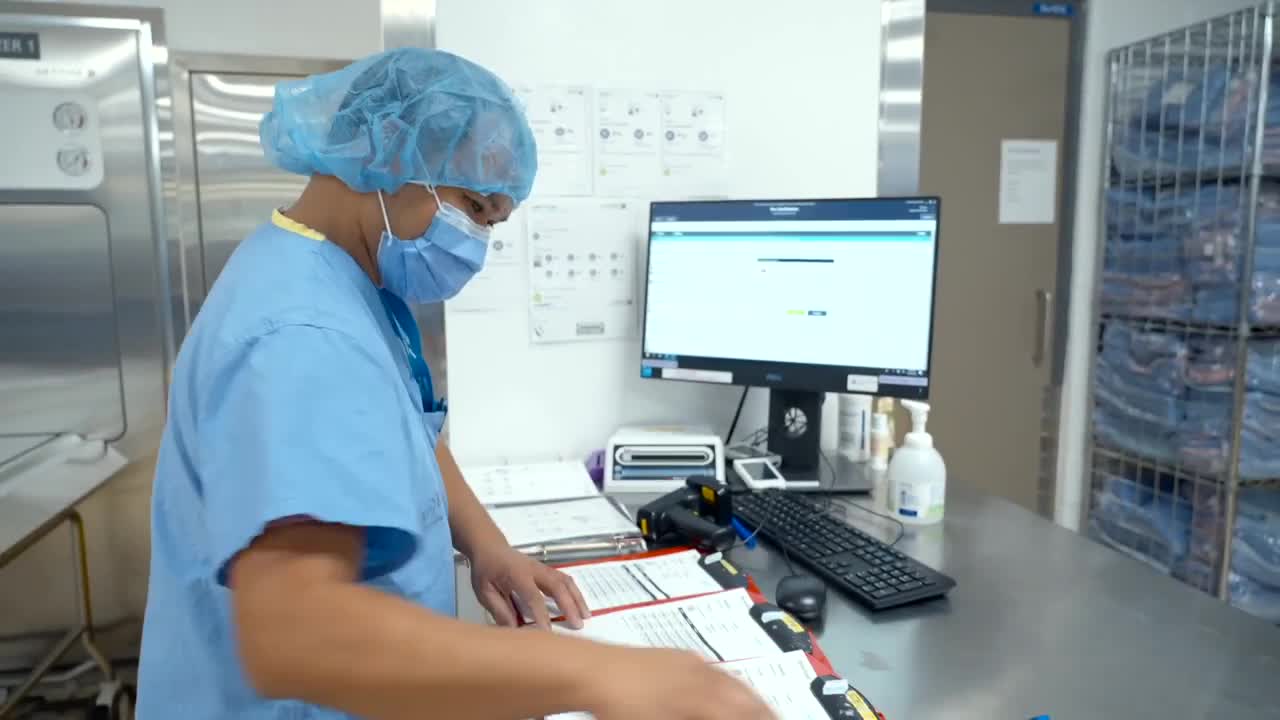

As North America's first fully-digital hospital, Humber River Hospital is constantly trailblazing new solutions across the healthcare continuum - and their Medical Device Reprocessing Department (MDRD) is no different. Getinge powers Humber River with some of the world's most advanced automation solutions and software, ensuring that every instrument is sterile for its next surgery. Workflow optimization is at the heart of this department - and Getinge is a proud partner to Humber River Hospital.

Designing a department? Renovating a department? Get in touch with our team.

One of the main benefits that I considered when choosing to partner with Getinge is that everything is under one umbrella. We have the [Sterile Processing] equipment, we have the consumables, we have the instrument tracking software, and we have the technical team to support us. Throughout the entire project, everything that I needed was available from Getinge.

Video & Photo Gallery

Explore Humber River's Sterile Processing Department without ever leaving your desk.

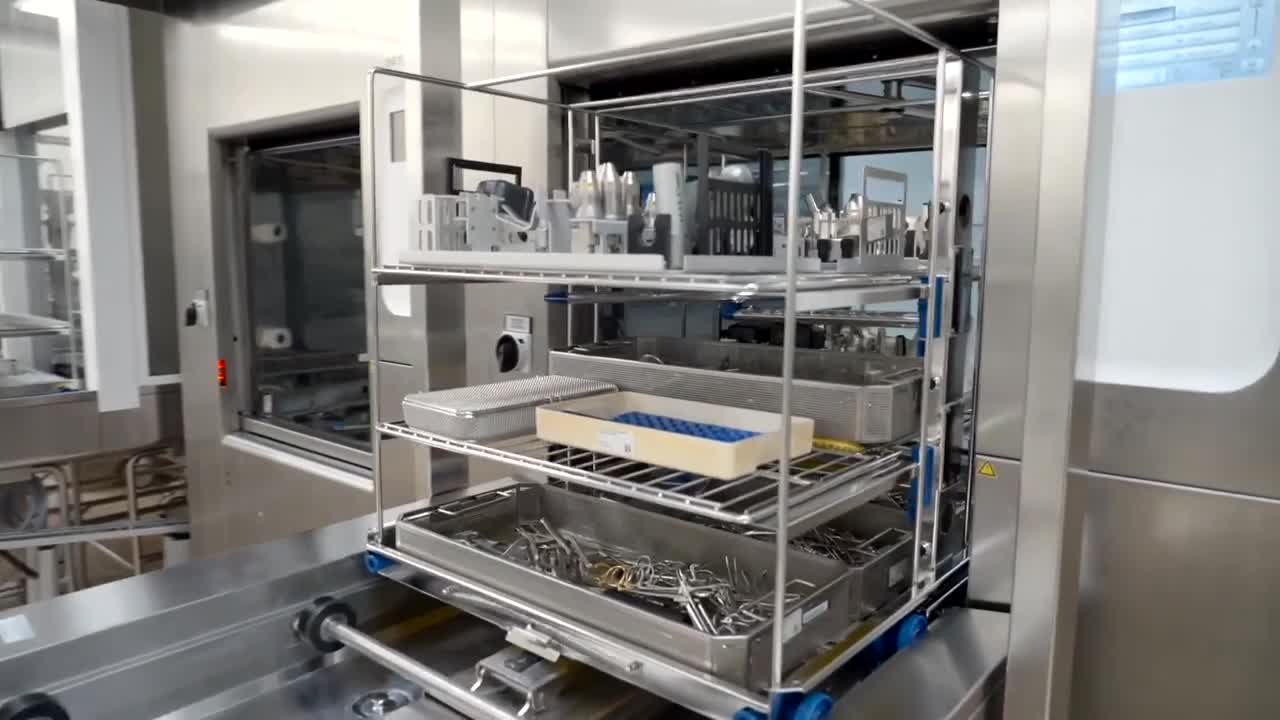

Washer Trolley Maneuvering

One of Getinge's strongest advantages is ergonomics. View the ease of washer-trolley manuvering.

CM320 with Service Tech

CM320 is prominently featured in Humber River's soiled zone, and is essential to their workflow.

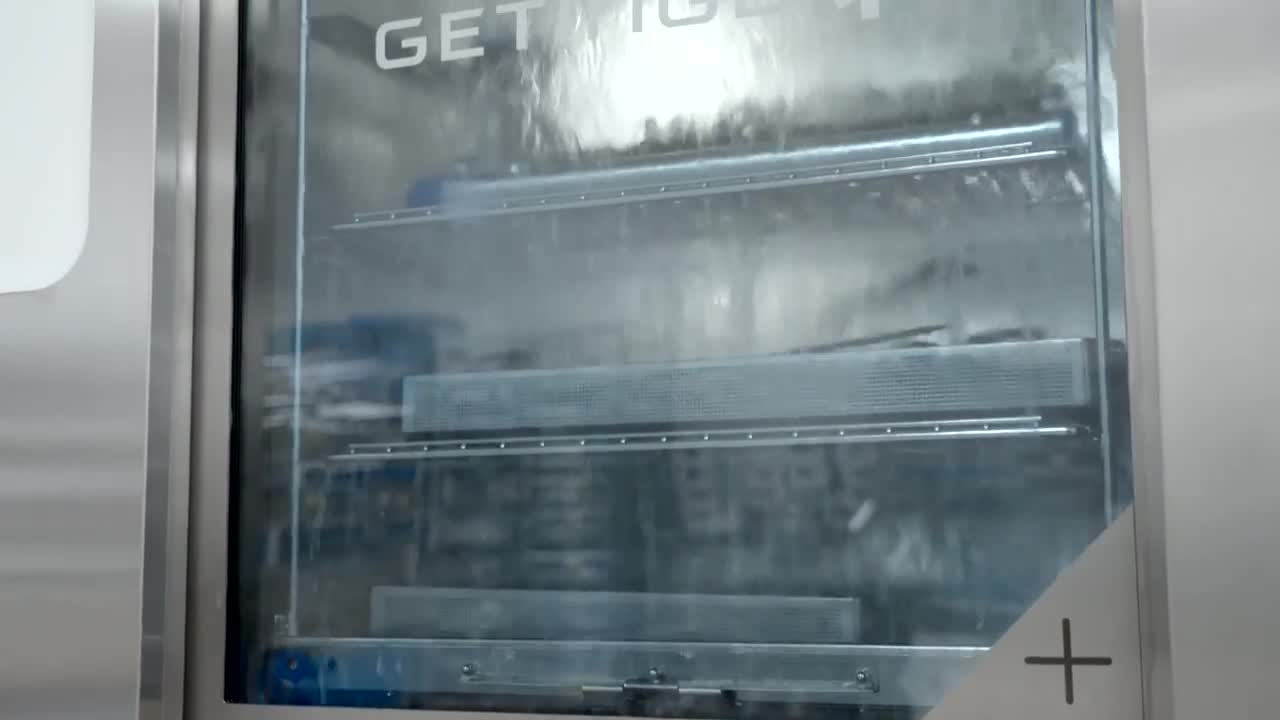

9100-Series Cart Washer In-Action

The 9100-series cart washer is designed for high-capacity spaces, and is critical to Humber River's workflow.

Sterilizer Trolley Maneuvering

Our trolleys are designed to minimize physical strain on staff. View just how smoothly they operate.

T-DOC Scanning and Sterilizer

T-DOC provides Humber River with complete instrument tracability. Learn how T-DOC interfaces with Sterilizer loading.

Sterlizer Automation

Humber River is one of the only facilities in Canada with Sterilizer Automation.

Technician at Sink

Our sinks are the first stop for many instruments. View a technican utilizing them.

CM320

Humber River Hospital is one of the few facilities in North America utilizing the full capabilities of CM320. View the multi-chamber washer!

The Process

Building the perfect Sterile Processing Department is a complex process involving meticulous planning. Here's a snapshot of what went into building Humber River Hospital.

Planning & Design

3D visualizations

2D drawings provide an overview of the workflow, the room functions and the proposed equipment’s placement and required space in the facility. 3D visualization help the space come to life, providing a realistic walk-through of how your future project will look. View this fly-through of the Humber River Hospital department

Receive, sort, pre-clean

After visual inspection, unclean items are either put straight on racks and loaded into the washer-disinfectors or manually cleaned.

Explore Soiled Zone solutions

On leaving the washer-disinfector, the clean (but not sterile) goods enter the clean zone for sorting, inspection and packing.

Explore Clean Zone solutions

From Sterilization to the OR

Sterile goods are stored on racks or in storage and distribution trolleys for further transport within the hospital.

Explore Sterile Zone solutions