Discover the benefit of ultrasonic cleaning

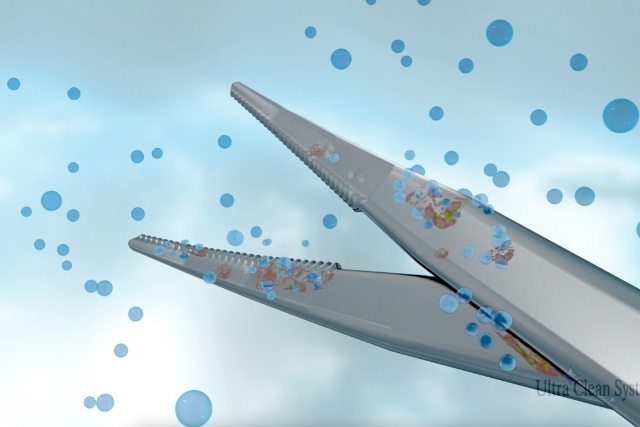

Getinge has 20 years of experience in the design and manufacture of innovative, versatile, and energy-efficient ultrasonic cleaning systems. Our ultrasonic systems are designed to accommodate all sterile processing needs, from small facilities to high-throughput trauma centers. We provide a comprehensive range of ultrasonic cleaning systems to fit any departmental need and budget.

Ultrasonic Solutions At-a-Glance

Ultrasonic Solutions At-a-Glance

Choosing the best ultrasonic for your SPD

What do you need to know to choose the best ultrasonic surgical instrument cleaner for your sterile processing department (SPD)? There are several things to consider. The most important are the number and type of instruments your department reprocesses on its busiest days and the space available for your machine.

TRT technology & benefits

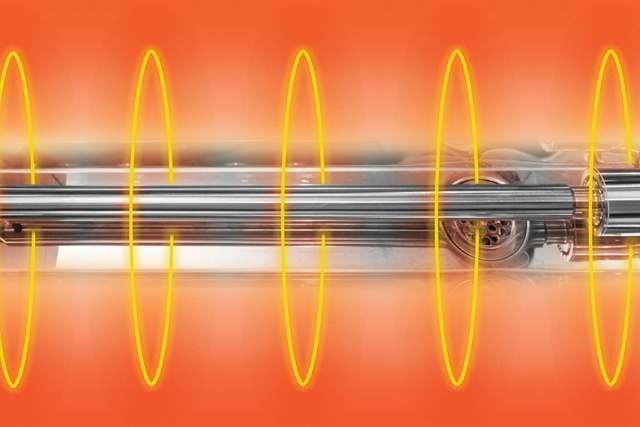

Thanks to its surgical-grade titanium and direct-in-water energy injection, TRT technology delivers:

- More power and reduced cleaning times compared to bonded transducers

- 8- to 13-minute adjustable ultrasonic cleaning cycles

- 15-minute dedicated da Vinci® robotic instrument cleaning cycles

- Longer life for the ultrasonic basin

- Less maintenance, reducing machine downtime and associated costs

The result? The surface area of each item in the tank is exposed to powerful TRT cavitation, enabling effective cleaning. In addition, cycle times are reduced by 5 minutes and the need for a separate degassing is eliminated, yielding a total time reduction of 10 minutes per cycle.

Many ultrasonic cleaning systems pass their energy from a series of surface-mounted transducers, via a bonding agent, through the metal basin, and into the water. This results in a power loss of around 20%. With TRT technology, this power loss is greatly reduced, thus the cleaning cycles are significantly shortened, allowing instruments to be available for the next case.

UV light technology & benefits

Getinge's Triton series ultrasonic cleaners’ UV filtration system destroys bacteria and viruses during the cleaning process.

After flushing any lumen or robotic instruments, the water passes over the UV light as it recirculates through the basin, killing any microbes dislodged during the cleaning process.

Getinge was the first company to incorporate this important safety feature into its technology.

More sterile reprocessing content

CE Series: Beyond the Bubble

This series, “Beyond the Bubble: An Inside Look at Ultrasonic Cleaners,” is focused on helping you understand the intricate anatomy that makes these unique cleaning devices such a critical piece of the reprocessing workflow. Read the 15 segments and take a quiz for two 2 CE credits. (Approved for HSPA and CBSPD)

Getinge Ultrasonic Solutions

Ultra Clean Systems, now a part of Getinge

Our ultrasonic systems are designed to accommodate all sterile processing needs, from small facilities to high-throughput trauma centers. We provide a comprehensive range of ultrasonic cleaning systems to fit any departmental need and budget.

NewSplash – Current Healthcare News

Central service professionals from many prominent facilities read NewSplash.

With NewSplash, you’ll be among the most informed leaders in the sterile processing and infection control spaces.

Give us a try. It’s truly free!

Explore our products

Find the right products and solutions for you